Block 3, MHDI Building, 86 Le Trong Tan, Phuong Liet Ward, 100000 Hanoi City, Vietnam

GMW’S OPERATING PRINCIPLE.

With many years of experience in dry lubrication solutions for rotating movements in high temperatures. We invest heavily in research and development of heat-resistant bearings for applications from common to complex…. We are committed to bringing customers genuine products and the best customer support policies with criteria such as:

CUSTOMIZED SOLUTIONS

With special design, easy to operate at temperatures from 150°C (302°F) to 450°C (842°F). High-temperature bearings are a product line we manufacture to solve problems related to high-temperature environments, dry environmental conditions and slow or fast rotation speeds.

In addition, we also research and develop low-temperature bearings down to (- 60) °C degrees for application in very low-temperature environments.

.

EXCELLENT QUALITY AND ATTRACTIVE PRICE

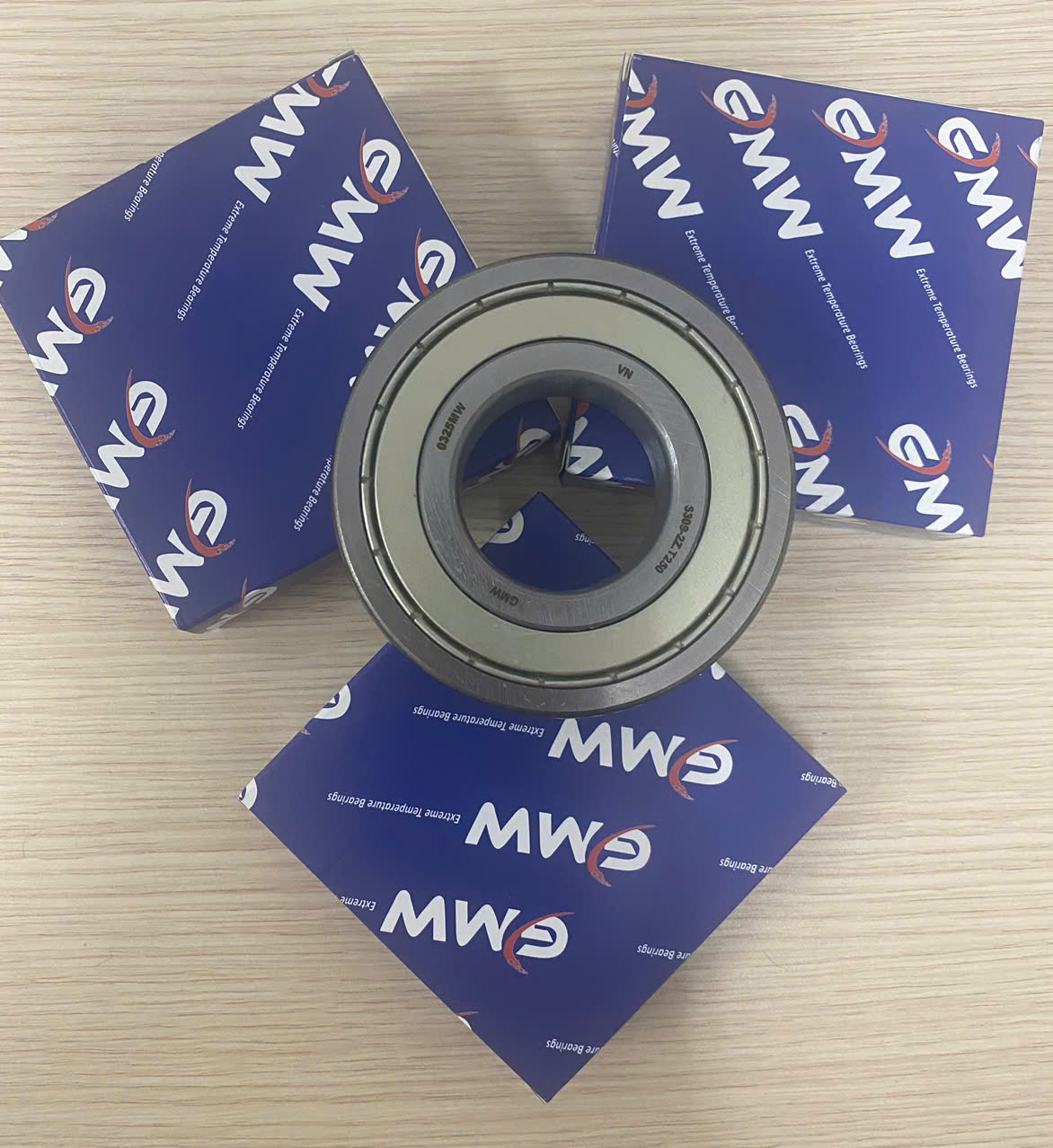

GMW Extreme Temperature Bearings are a special series of bearings manufactured to solve problems related to high or low temperature environments, dry environmental conditions with low rotation speeds and fast rotation.

Our company gathers a team of professional sales staff and a team of experienced technicians in the field of distribution and technical services.

We are committed to providing customers with high-quality products, suitable for many applications, and the best customer support policies.

MAXIMUM FLEXIBILITY

We have researched and developed (R&D) “heat-resistant bearings” with special designs, easy to operate in a high-temperature range from 150°C (302°F) to 450°C (842°F), using high-strength steel materials, treated with anti-wear manganese phosphate coating according to the DIN EN ISO 9717 standard.

We combine with leading heat-resistant greases from brands such as: DuPont, Kluber, Fuchs, Beslux, Cogelsa and Kyodo Yushi to create lubrication solutions.

GMW-branded products have been highly appreciated by customers for their quality in practical applications.

FLEXIBLE PAYMENT TERMS

When you purchase products from GMW Vietnam Co., Ltd, you can pay by the following methods:

- Cash payment

- Payment by bank transfer

- Cash on delivery

Products

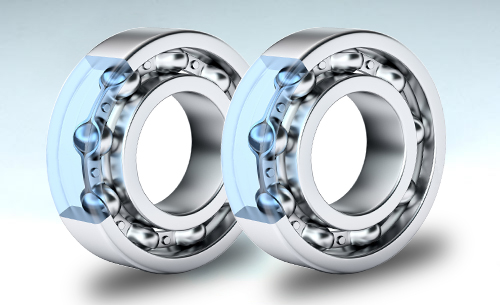

We specialise in rotating solutions for high-temperature applications, mainly in bearings. Our main product lines include heat-resistant deep groove ball bearings, heat-resistant tapered roller bearings, heat-resistant spherical roller bearings, heat-resistant pillow block bearings and heat-resistant cam follower bearings. With large production capacity, we meet all product codes as required by customers nationwide with the criteria of PRICE & QUALITY.

Multi-industry applications

All of our GMW bearings are made from high-strength steel grades such as AISI 52100 / SUJ2 / GCr15 / S440C. Bearings with C4 and C5 clearance design, coated with manganese phosphate combined with the most suitable grease for each temperature level as a lubrication solution. Our GMW heat-resistant bearings are especially useful for applications in high-temperature conditions such as the installation of high-pressure aluminium casting equipment (die-casting), load wheels (gong) used in brick kilns, kilns for the ceramic industry, aluminium kilns, drying kiln rollers in the processing industry, conveyor rollers in the hot-rolled steel industry, float glass production, the textile dyeing industry, the manufacturing of heat-resistant motors, drying fans, heat-resistant oil pumps, etc…

Hot rolled steel

Conventional steel bearings do not last long in high-temperature environments such as steel production. The housing expands, the polymers in the cage decompose and the lubricant evaporates. Any of these factors can cripple the bearing and stop production, let alone all three at the same time.

Therefore, GMW has developed a range of special bearings designed specifically for use in extremely high-temperature applications such as steel production. The HT4 suffix, up to a max of 400°C (752°F), is made from high-strength steel materials such as AISI 52100 / SUJ2 / GCr15, and lubricants with special grease base oil MoS₂ help hot-rolled steel conveyor rollers operate smoothly and safely in production.

Read moreDIE-CASTING AND ALUMINUM PRODUCTION

In the high-pressure die casting process, molten aluminium or aluminium alloy is removed from the furnace and poured into the mould at a slow speed and high pressure. Depending on the metal used, the material is fed into the mould continuously with the molten metal at a temperature of about 600°C – 700°C.

GMW with the suffix HT1 (350°C) and HT2 (280°C) are manufactured with high-performance, low-friction riveted cages. The manganese phosphate coating of GMW HT1 (350°C) and HT2 (280°C) helps the bearing ensure good corrosion resistance and adhesion of the lubricant. There are two grease options, (Mos2) with HT1 and (PTFE) with HT2, which will ensure the equipment is operated safely and efficiently in production.

Read moreROLLERS AND WHEELS OF DRYING SYSTEM

GMW suffix HT4U high-temperature bearings are designed to increase reliability, reduce complexity and reduce environmental impact at operating temperatures up to 450°C (842°F). The Suffix HT4U (Ultra) high-temperature bearing (max 500°C (932°F)) with paste lubrication solution: when the equipment reaches extremely high temperatures, the graphite-containing high-temperature paste for thin-film lubrication will form a paste to prevent bearing seizure, very suitable for applications in aluminium furnace trucks, brick kilns, float glass…

Since GMW high-temperature bearings correspond to ISO sizes of grease-lubricated bearings, production efficiency and cost savings can be achieved with just a simple change to the GMW bearing solution.

HEAT-RESISTANT ELECTRIC MOTOR

There is always some variation in the operating temperature of bearings in motors. Individual operating temperatures depend on factors such as the application of the motor and the ambient temperature. However, as a guide, 170°F or 80°C should be considered normal. As temperatures rise from this point, the risk of serious damage and engine failure also increases. At 190°F or 90°C, the temperature alarm will operate. It is important not to ignore them and to take immediate action to find and treat the cause of the temperature increase. GMW with the suffix T150-Basic and the suffixes T250 and T250X are designed for high and medium speeds, operating durably in the temperature range from 150°C to 250°C to help the motor operate stably in harsh environments.

1) Prevent metal corrosion.

2) Reduce friction and wear, prolong bearing life.

NEW PRODUCT

We specialise in rotating solutions, combining our experience in designing bearings for high-temperature applications. Therefore, we continuously invest in R&D to develop new product lines or upgrade existing ones with the support of specialised software.

SUSTAINABLE DEVELOPMENT !

GMW is a supplier of high-temperature bearings and innovative solutions that help industries become more competitive and sustainable. By making products more efficient, long-lasting and repairable, GMW helps customers improve the performance of rotating equipment and reduce their environmental impact. GMW’s rotating products include high-temperature bearings, high-temperature lubrication solutions, condition monitoring and services.

Contact usProduct Catalogue

Below, GMW provides the main types of heat-resistant bearings. A catalogue of GMW heat-resistant bearings with a variety of types and sizes is also attached for customers to refer to and choose the product they need to apply.

QUALITY AND PORTFOLIO

We firmly believe that a rigorous quality policy is required to comply with the reliability, deadlines and optimised service portfolios required by our customers and suppliers.

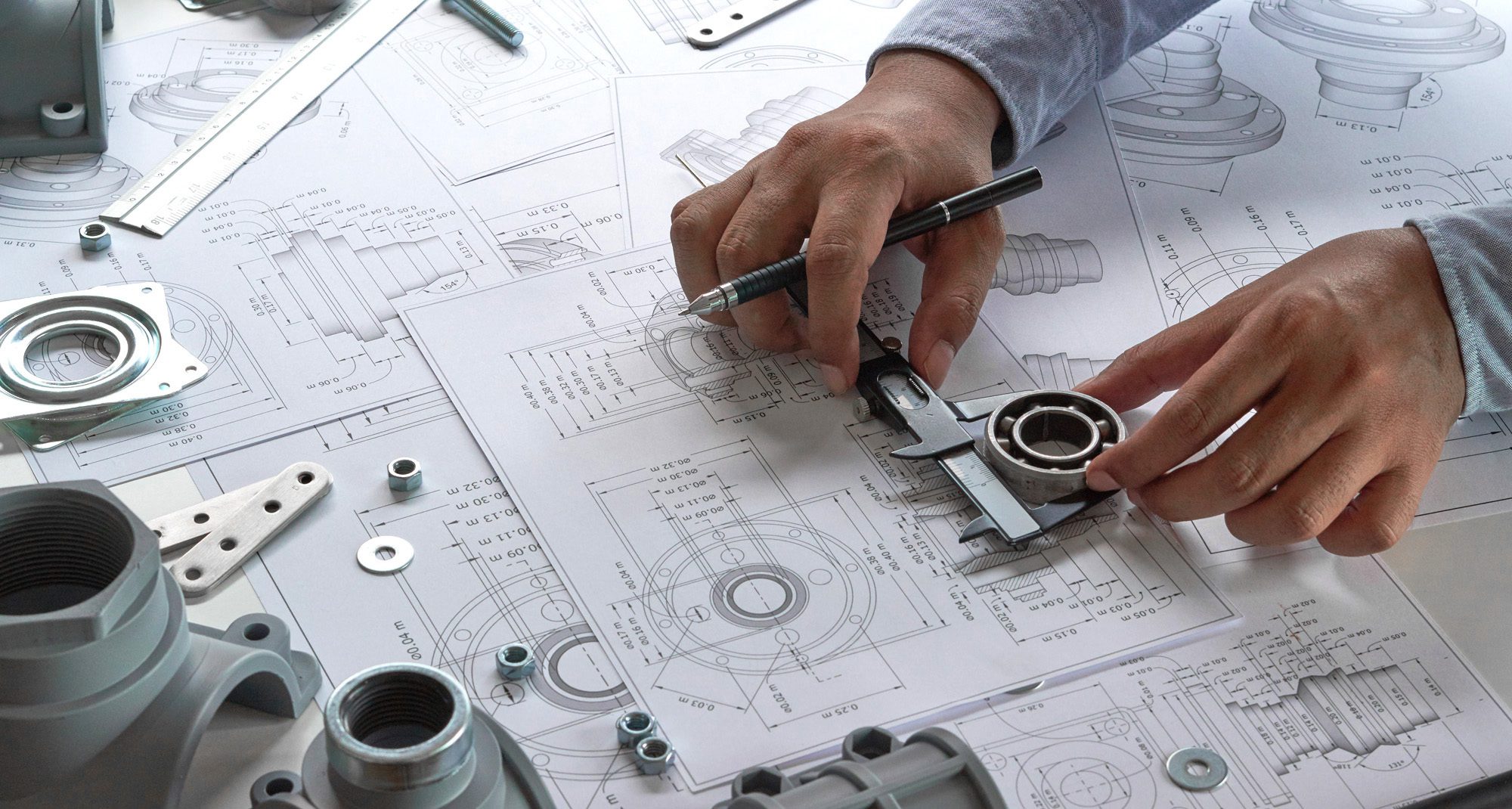

MACHINING

DIN ISO9717

LUBRICATION STANDARD

![]()

+ 500

HAPPY CUSTOMERS

+ 100

COMPLETED PROJECTS

CUSTOM FABRICATION

Machining custom bearings is an advanced engineering process that involves the use of computerised machinery to design, manufacture, and finish custom parts or assemblies.

An important decision that impacts both cost and quality in this process is the choice of production quantity – the choice between low and high lot sizes.

-

Choosing low-volume manufacturing can provide benefits such as lower initial costs, faster turnaround times, and more flexibility for design modifications.

-

On the other hand, mass production usually has lower unit costs and is well suited for large-scale production where the design is unlikely to change significantly over time.

TECHNICAL SUPERVISION

Technical supervision is an important position in the process from product selection to completion to operation.

We provide technical support to team members or customers as needed. This may include answering technical questions, providing guidance on the use of products or services, and assisting in resolving technical issues.

In the event of a technical problem or error, we often have to make a decision about adjusting or repairing the product or other technical process to resolve the problem.

OEM SUPPLY

In the OEM model, we manufacture specialised products or finished components according to customer specifications.

As a manufacturer of speciality products, our OEM model offers advanced manufacturing expertise. We have also established a supply chain, access to high-quality raw material suppliers, and established quality processes and testing.

Our OEM model allows us to develop many production ideas and test many different models. This allows customers to explore the market and quickly penetrate new and potential areas.

CONSULTING AND TRANSFER

Consulting is the process of providing expert and knowledgeable guidance, information, opinion or advice on a particular issue or situation. This process is usually carried out by us by an expert or person with in-depth knowledge in the field related to the issue being discussed.

We grant the right to use the features of our products to organisations and individuals using the WIN-WIN principle.